Edge banding machine is used to apply a strip of any material to the edges of woodwork or furniture pieces. It helps enhance the look and finish of the furniture. These machines are designed to work with various materials but are largely used for wood furniture. Wood furniture with rough edges can be unpleasing to the eyes. By covering the rough edges, an edge banding machine for wood ensures the furniture looks visually appealing and enhances the curb appeal of the overall background.

Edge banding machine's primary use is to improve furniture and cabinetry aesthetics. They help create a polished appearance by concealing the raw edges of the underlying material. Another purpose that these edge banding machines serve is protection. Rough edges of any material can be harmful. For instance, a splinter from the raw edges of plywood furniture can enter a finger and cause pain and even infection. Plywood edge banding can cover the exposed wood to prevent the user from getting hurt by a splinter. Edge banding machines also protect the furniture itself. Moisture and other environmental factors can infiltrate the edges of any material. Implementing edge banding to furniture can prevent this. Thus, it can keep furniture from damage like wrapping or swelling.

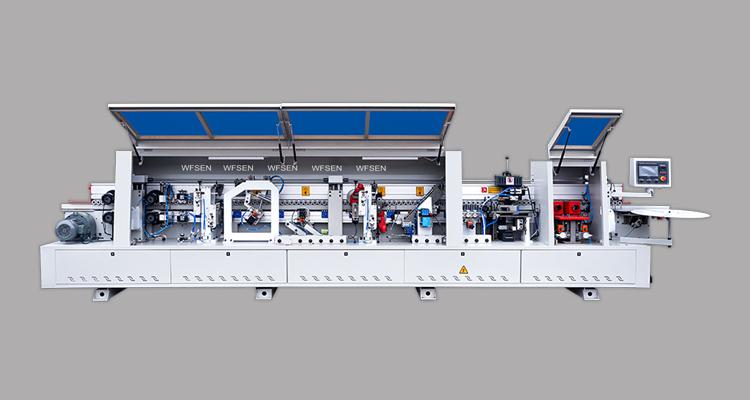

Additionally, edge banding machines offer versatility. They can accommodate different materials, ranging from PVC and ABS to wood veneer and melamine. This allows the manufacturers to cater to the diverse needs of customers. It also enables the end customers to choose from various options. Another of the many uses of edge banding machine is their precision. This is done with the help of an automatic edge banding machine that can automate applying edge banding. With automation, edge banding machines can improve precision and reduce manual labor and time. It also ensures consistent and accurate implementation, thereby contributing to the overall quality of the end product.